James Watt

Scottish inventor, mechanical engineer, and chemist.

Whose development of the steam engine was fundamental to the Industrial Revolution.

Born 19 January 1736, Scotland

Died 25 August 1819 England

While working as an instrument maker at the University of Glasgow, Watt became interested in the technology of steam engines. He realised that contemporary engine designs wasted a great deal of energy by repeatedly cooling and reheating the cylinder. Watt introduced a design enhancement, the separate condenser, which avoided this waste of energy and radically improved the power, efficiency, and cost-effectiveness of steam engines. Eventually, he adapted his engine to produce rotary motion, greatly broadening its use beyond pumping water.

Watt attempted to commercialise his invention, but experienced great financial difficulties until he entered a partnership with Matthew Boulton in 1775. The new firm of Boulton and Watt was eventually highly successful and Watt became a wealthy man. In his retirement, Watt continued to develop new inventions though none was as significant as his steam engine work.

As Watt developed the concept of horsepower, the SI unit of power, the watt, was named after him.

James Watt was the eldest of five children, and came from a distingushed family. The Watt family's wealth came in part from Watt's father's trading in slaves and slave-produced goods. Watt's parents were Presbyterians and strong Covenanters, but despite his religious upbringing he later became a deist (athiest).

In 1756 James settled in Glasgow, intent on setting up his own instrument-making business. He was still very young and, having not had a full apprenticeship, did not have the usual connections via a former master to establish himself as a journeyman instrument maker.

Watt did not actually invent the steam engine, but dramatically improved the efficiency of the existing Newcomen engine by adding a separate condenser. In 1759, Watt's friend, John Robison, called his attention to the use of steam as a source of motive power. The design of the Newcomen engine, in use for almost 50 years for pumping water from mines, had hardly changed from its first implementation. Watt began to experiment with steam, though he had never seen an operating steam engine. He tried constructing a model; it failed to work satisfactorily, but he continued his experiments and began to read everything he could about the subject. He came to realise the importance of latent heat—the thermal energy released or absorbed during a constant-temperature process—in understanding the engine. Understanding of the steam engine was in a very primitive state, for the science of thermodynamics would not be formalised for nearly another 100 years.

In 1763, Watt was asked to repair a model Newcomen engine belonging to the university. Even after repair, the engine barely worked.

After much experimentation, Watt demonstrated that about 3/4 of the thermal energy of the steam was being consumed in heating the engine cylinder on every cycle. This energy was wasted because, later in the cycle, cold water was injected into the cylinder to condense the steam to reduce its pressure. Thus, by repeatedly heating and cooling the cylinder, the engine wasted most of its thermal energy rather than converting it into mechanical energy.

Despite a potentially workable design, there were still substantial difficulties in constructing a full-scale engine.

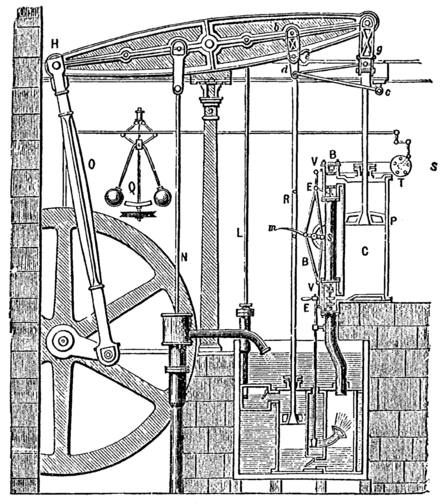

Steam engine - designed by Boulton and Watt, 1784

Substantial backing came from John Roebuck, the founder of the celebrated Carron Iron Works near Falkirk, with whom he now formed a partnership. Roebuck went bankrupt; and Matthew Boulton, who owned the Soho Manufactory works near Birmingham, acquired his patent rights.

First engines

In 1776, the first engines were installed and working in commercial enterprises. These first engines were used to power pumps. The design was commercially successful, and for the next 5 years, Watt was very busy installing more engines for pumping water out of mines.

These early engines were not manufactured by Boulton and Watt, but were made by others according to drawings made by Watt, who served in the role of consulting engineer. These were large machines. The first, for example, had a cylinder with a diameter of some 50 inches and an overall height of about 24 feet, and required the construction of a dedicated building to house it. Boulton and Watt charged an annual payment, equal to 1/3 of the value of the coal saved in comparison to a Newcomen engine performing the same work.

Over the next 6 years, he made a number of other improvements and modifications to the steam engine. A double-acting engine, in which the steam acted alternately on both sides of the piston, was one. He described methods for working the steam "expansively" (i.e., using steam at pressures well above atmospheric). A compound engine, which connected 2 or more engines, was described. Two more patents were granted for these in 1781 and 1782.

Another important invention, one which Watt was most proud of, was the parallel motion linkage, which was essential in double-acting engines as it produced the straight line motion required for the cylinder rod and pump, from the connected rocking beam, whose end moves in a circular arc. This was patented in 1784.

A throttle valve to control the power of the engine, and a centrifugal governor, patented in 1788, to keep it from "running away" were very important.

These improvements taken together produced an engine which was up to 5 times as fuel efficient as the Newcomen engine.

Watt steam engine

Other discoveries

Copying machine

Portable Copying Machine by James Watt & Co. Circa 1795

Before 1780, there was no good method for making copies of letters or drawings. The only method sometimes used was a mechanical one using multiple linked pens. Watt at first experimented with improving this method, but soon gave up on this approach because it was so cumbersome. He instead decided to try to physically transfer some ink from the front of the original to the back of another sheet, moistened with a solvent, and pressed to the original. The second sheet had to be thin, so that the ink could be seen through it when the copy was held up to the light, thus reproducing the original exactly.

Watt started to develop the process in 1779, and made many experiments to formulate the ink, select the thin paper, to devise a method for wetting the special thin paper, and to make a press suitable for applying the correct pressure to effect the transfer. All of these required much experimentation, but he soon had enough success to patent the process a year later. Watt formed another partnership with Boulton (who provided financing) and James Keir (to manage the business) in a firm called James Watt and Co. The perfection of the invention required much more development work before it could be routinely used by others, but this was carried out over the next few years. Boulton and Watt gave up their shares to their sons in 1794.

It became a commercial success and was widely used in offices even into the 20th century.

Chemical experiments

From an early age, Watt was very interested in chemistry. In late 1786, while in Paris, he witnessed an experiment by Claude Louis Berthollet in which he reacted hydrochloric acid with manganese dioxide to produce chlorine. He had already found that an aqueous solution of chlorine could bleach textiles, and had published his findings, which aroused great interest among many potential rivals.

When Watt returned to Britain, he began experiments along these lines with hopes of finding a commercially viable process. He discovered that a mixture of salt, manganese dioxide and sulphuric acid could produce chlorine, which Watt believed might be a cheaper method. He passed the chlorine into a weak solution of alkali, and obtained a turbid solution that appeared to have good bleaching properties. He soon communicated these results to James McGrigor, his father-in-law, who was a bleacher in Glasgow. Otherwise, he tried to keep his method a secret.

With McGrigor and his wife Annie, he started to scale up the process, and in March 1788, McGrigor was able to bleach 1,500 yards (4,500 feet) of cloth to his satisfaction.

About this time, Berthollet discovered the salt and sulphuric acid process, and published it, so it became public knowledge. Many others began to experiment with improving the process, which still had many shortcomings, not the least of which was the problem of transporting the liquid product. Watt's rivals soon overtook him in developing the process, and he dropped out of the race. It was not until 1799, when Charles Tennant patented a process for producing solid bleaching powder (calcium hypochlorite) that it became a commercial success.

By 1794, Watt had been chosen by Thomas Beddoes to manufacture apparatuses to produce, clean and store gases for use in the new Pneumatic Institution at Hotwells in Bristol. Watt continued to experiment with various gases for several years, but by 1797, the medical uses for the "factitious airs" (artificial gases) had come to a dead end.

In 2009, the Bank of England announced that Watt would appear on a £50 note (alongside Matthew Boulton) with an image of Watt’s steam engine and the quote “I can think of nothing else but this machine”.